|

|

Before application of paste wood filler, the guitar gets a good dusting with compressed air. |

|

|

And, after the open grain is filled, the body is wiped down with naphtha to make sure it is perfectly clean for the first coats of finish. |

|

|

This is the spray booth, where the first coats of catalyzed undercoat are applied. |

|

|

After the undercoat is catalyzed by radiation with high intensity ultraviolet light, the guitar body is "scuff" sanded in preparation for the subsequent finish coats. |

|

|

Back in the spray booth, traditional nitrocellulose lacquer is sprayed in successive coats to build the gloss finish. By the way, that's some fine Brazilian rosewood, isn't it? |

|

|

Nearby, there's a special heated drying room, where the guitar bodies and necks spend a couple of weeks drying. In fact, it is the extended drying time that's partly responsible for Fox guitars having as fine a finish as any in the business. |

|

|

When the finish is fully cured, it gets a final buffing with ultra fine polishing compound. |

|

|

The buffing rig is another Fox shop-built setup, and it is housed in its own clean room with plenty of light and room to maneuver. |

|

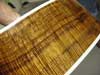

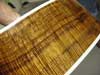

Look at the depth of shine on this koa guitar side! |

|

Well, we've made it to the final room and workstation in the assembly process, where frets get installed and neck meets body. That guy with his back to us is Todd Taggart again, taking another photo. Apparently I wasn't the only spy in the factory that day! |

|

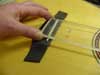

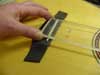

In case you're wondering about the acrylic jig on the fingerboard, stay tuned, because I made one for myself, and I'll be posting an article about it. |

|

It's a neck alignment gauge, and has a mock saddle at the bridge end. With this gauge, the precise location of the bridge is set easily. |

|

In fact, after the neck is bolted in place, the end of the fingerboard and bridge are glued at the same time. |

|

|

To overhang the binding on the edge of the fingerboard, each end of each fret is cut and filed by hand. |

|

|

This is a mock fingerboard, used to judge the length of each fret. As the frets are trimmed, they are stored in marked holes. |

|

|

Sets of frets for about a dozen guitars are cut and trimmed in one session. |

|

|

I think I'll be making up a rig like this one. It's a fixture for resting the neck while installing frets. Unlike most of the fixturing in a guitar factory, this one looks ideal for repair work, too. |

|

|

The guitar body sits against a padded rest at one end. |

|

|

And the neck rest is raised and adjusted top provide support along the entire length of the neck. It takes only a couple of seconds to get a perfect alignment on the neck rest. |

|

|

Then, with a protective cover on the guitar body, we're all ready for the fretting operation. |

|

|

Just as in repair, now is the last opportunity to achieve a perfectly level fingerboard. Sandpaper stuck onto a piece of heavy plate glass makes a fine sanding block for this operation. |

|

|

A plastic hammer leaves no marks in the frets as they are tapped in position. |

|

|

And, after painstakingly leveling and rounding each fret, the fingerboard is complete. This fret shows the trademark hemispherical end treatment. |

|

|

Look as closely as you may, you'll find the attention to detail that marks a fine handmade guitar. |

|

|

Bridge pin holes are drilled, and chamfered with a modest hand drill. |

|

|

Little string ramps are buzzed into the bridge with a Dremel tool. |

|

|

Just to dress up the bridge a bit, each string ramp is chamfered, too. |

|

|

At the south end of the guitar, the center of the end wedge is located, |

|

|

drilled, and followed by |

|

|

a touch with a hand reamer |

|

|

to fit the traditional tapered end pin. |

|

|

Remember those countersunk tuner holes? Well, the buffing compound tends to build up in them, and is cleaned out with cotton swab. |

|

|

Each tuner is lined up for the best symmetrical appearance. |

|

|

Once the tuners are installed, the peghead achieves its unique look. |

|

|

The moment approaches. The last operation is stringing and tuning. |

|

|

And, here we are, right where we started, as Charles checks out the newest Fox guitar. |

|

|

As I was packing up, I caught sight of this one, headed for Greg Allman. . . |