Nothing like redundancy when you can turn it to your advantage. Besides the big resawing bandsaw, Ted has a metal cutting bandsaw for tooling, and a general woodworking bandsaw:

Ted makes his own tailpieces, too, so (naturally) he has this fourth bandsaw just for cutting brass:

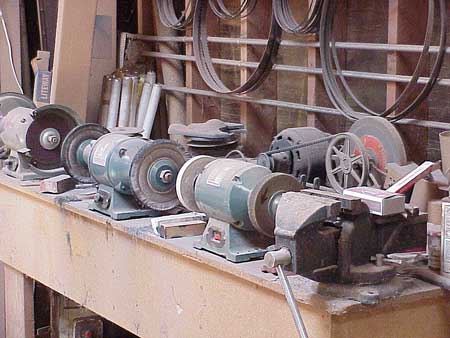

I have a grinder in my shop. Ted has four:

Ooh! What's this?

It's a guitar in progress for none other than fellow guitar maker, Jeff Traugott!

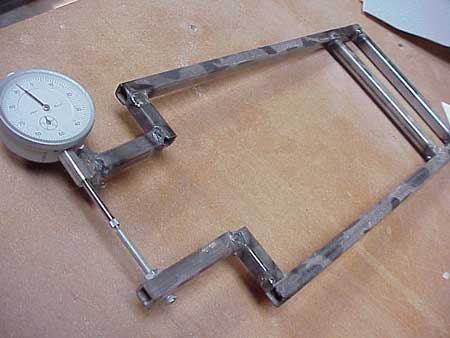

Ted welded up his own thickness gauge:

A router hides under a counter top:

It gets raised up to see duty making the tuner buttons, tailpieces, and fingerrests.

I had to ask about this one. Ted uses the "diagonal split block inlay" style. Instead of cutting each triangular piece out and inlaying them separately. Ted takes a rectangular block of pearl, and cuts a slot almost all the way through it on a diagonal with this machine:

Then he inlays the block with an ebony strip, and inlays the resulting rectangular block in one piece.

In order to plane the figured woods, Ted fitted his Oliver planer with a separate gear motor to control the feed:

You can see the motor and gear drive hanging off the right side. He claims he can slow the feed down to about a foot a minute if he wants to plane figured maple with no tearout.

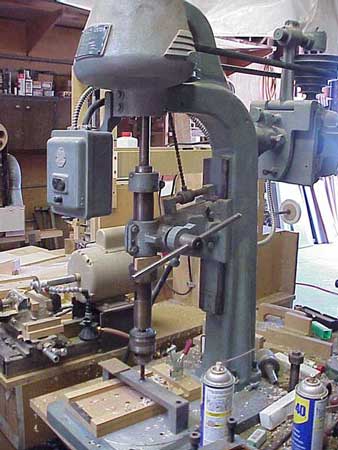

An old boring machine fitted up for drilling pegheads:

I don't think I've ever visited an individual luthier who employs as many tools as Ted Megas! His ingenuity shows in every corner of his large shop. With his attention to detail in tooling, it's no wonder his instruments come out looking (and sounding) so fine!