Page 1 of 2

An introduction to

Amalgamating Lacquer

© Frank Ford, 6/7/98; Photos by FF, 6/2/98

Now, here's a checked and lifting finish.

This is a 1948 Martin O-18T (tenor guitar.) I'd say it has been subjected to extremes of temperature and humidity. The lacquer has checked all over, but the neck is the most severely affected, with the finish actually beginning to lift and fall off. You can see a couple of places where the finish is missing at the edge by the fourth string tuner.

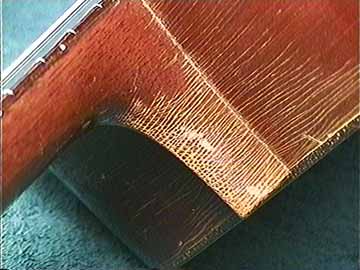

Let's look at the back of the neck:

Things aren't much better here, either:

The checking runs over the length of the neck as well, but doesn't show well in this photo.

Notice that checks are radiating out from the neck block into the sides. I find it significant that the side checks are far worse in the areas over the neck and end block, and over the linings. Out in the unsupported area of the sides, there are hardly any checks. The top and back of the body are relatively unaffected.

My job this time is to amalgamate the checked finish on the neck only. The body really doesn't look too bad, and the finish is not even beginning to lift or loosen except on the neck, especially the peghead and heel.

Nitrocellulose lacquer is basically a solid dissolved in solvent, and it cures entirely by evaporation. Because of that, it can also be redissolved in its own solvent. The other finish that works that way is shellac, but it loses its solubility completely after a few decades. Varnishes, catalyzed finishes and paints cure by a variety of chemical changes in addition to solvent evaporation, so they lose their solubility, and some can't be redissolved at all.

I'm going to use a chemical generally known as CELLOSOLVE® , or Butyl

CELLOSOLVE® Solvent. It is has a much higher boiling point than acetone or regular lacquer thinner. In fact, it evaporates so slowly, it feels more like oil if you get some on your hands.

Either CELLOSOLVE® or "retarder thinner" will work well in this

application. To avoid having to add the little registered trademark bug (®)

all over the place, I'll use the word "amalgamator" as a generic.

Retarder thinner is added to lacquer to slow the drying time. 10% retarder thinner in the mixture of lacquer will really help prevent blushing when spraying in high humidity.

The whole idea here is to dissolve the finish enough to soften it and cause it to get really sticky so it will fall back to the surface of the wood and stick just the way it did when it was first sprayed on. The trick is to use enough amalgamator to get the job done, but not so much that I cause the entire finish to thin and run.

I'll start by brushing amalgamator over the entire surface, and allowing it to run into the cracks and under the finish:

It's really dramatic, isn't it? The finish clears immediately as the gaps are filled between the finish and the wood.

But, notice the blisters all over the area I've just brushed. There, the amalgamator didn't have a chance to get under the finish.

Here's the back of the peghead, same process:

With the same results.

I'm afraid you'll have to take my word for the next part. I don't have good photos.

The little blisters covered both front and back of the peghead, and were scattered at the heel. They are more difficult to correct because they are spots where the finish doesn't touch the wood underneath. I could puncture each one and float on some amalgamator, but that could take forever because of the number of these little spots.

Instead, I sprayed the neck with straight amalgamator I sprayed on as much as I could without having it drip. Half an hour later I looked at the results, and nothing seemed different. I sprayed another coat, and then half an hour later, a third.

More

1

2

Back to Index Page