New Bone Roller

© Frank Ford 2003; Photos by FF

Unlike their Nineteenth Century bone counterparts, today's classical guitar rollers are made of plastic:

And, yes plastic does have a tendency to deteriorate over time. The most common failure is a simple crack, but the roller on this 1949 Martin classical guitar has actually started to decompose:

Today, the guitar in question is a 1930 Santos Hernandez flamenco. While it doesn't have its original tuners, it does have a fine set of vintage German tuners, which deserved a bit of preservation. One of the rollers has cracked off completely, revealing a stubby little brass shaft:

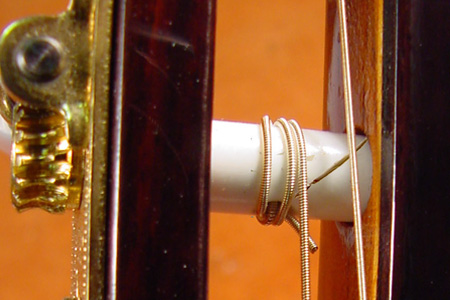

These days, it's more common to have the brass shaft running through the entire plastic roller, which is why the roller in the first photograph hasn't broken off the shaft.

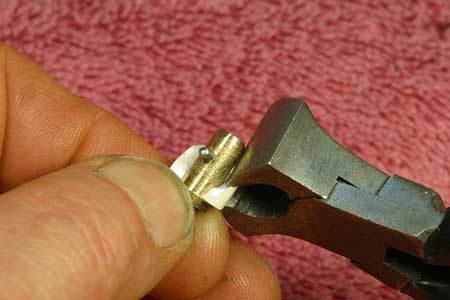

Separated from its parent, this little fellow doesn't look so tough:

But it would be nearly impossible for me to find a replacement roller mounted on a shaft that would actually fit the diameter of the hole in the plate or the square keyed hole in the gear cog. So, I chose to upgrade with a new bone roller. Compared to the labor involved in such a transplant, the cost of a natural bone roller is insignificant, so it makes sense to use the better material rather than simply sticking on another piece of plastic.

My fret pulling flush cutting end nippers made quick work of the remaining plastic roller:

Recently I was able to acquire some nice 10 mm turned bone roller blanks, and I chucked one into my drill press. Holding the appropriate drill vertically in the drill press vise, I was able to drill a hole centered nicely in the bone blank:

With the brass shaft inserted in the new roller, I drilled a 1/16" hole for the retaining pin:

I keep some 1/16" diameter steel welding rod around the shop for various uses, and I took a piece of it, stuck it through the small hole, and filed it off neatly:P

The little steel pin would be hidden beneath the wood of the peghead once the tuners were back in position.

Another 1/16" hole for the string completed the job:

Back in business:

Back to Index Page