Here's how I go about installing a

New Plastic Tuner Button

© Frank Ford, 1998, 2003; Photos by FF

Well, here's another fine mess you've gotten me into:

This button is dead. It's shrunken with age, become brittle and cracked. It has the

structural integrity of a charcoal briquette!! If it doesn't crumble when you try

to tune it this time, it will next time. The only cure is replacement.

A large number of tuners made during the 1940s and 50s have these white buttons

that deteriorate severely with age. They appear most often on the Kluson tuners used

by Martin, Gibson, Harmony and others. The buttons were originally white plastic,

but the plastic is a different material than that used on the tuners used from 1900

into the 1930s. Thankfully, THOSE tuner buttons are still doing fine!

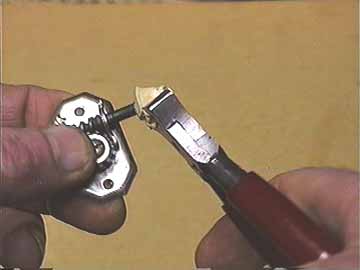

I like to "bite" the button with my fret removal nippers:

They're very sharp and make quick work of the dead button:

Here's the shaft with the button removed:

The end of the shaft has been mashed to form these little "wings"

that are aligned with the long axis of the button.

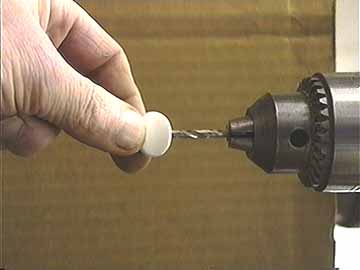

You can buy the perfect reproduction buttons from Stewart MacDonald or AllParts.

The only thing they don't tell you is that the hole is nowhere near the right

diameter, or even the right shape:

It's exactly the right depth, though, and you can use that to your advantage.

(I have no idea why the tuners come with such a funny little hole.)

I just select a drill bit the same diameter as the round shaft of the tuner

and drill out the button. That means 9/64" most of the time. I hold the

button by hand so I can easily feel the drill when it hits the bottom of the

original hole.

With the hole drilled just right, it's a simple matter to press on the button:

Here, I'm using my Versa-Vise, making sure that corner of the jaw meets right

on the end of the worm shaft. I don't want to strain the little bearings by

pressing anywhere else on the tuner body!

Once pressed on, the job is done, and the tuner really does look and work like

new:

If the shaft has little splines formed on its end instead of the large wings,

I may run a very little super glue into the hole before pressing on the button.

Gotta be careful, because the first time I tried the glue, I shot some glue

right back out with the pressure of inserting the shaft!

When I bought my first batch of these buttons, it came with the erroneous instruction

that all you have to do is press the button right onto the shaft. Here's the

result - a bulging and cracked button:

It's better, I think, to drill the appropriate hole.

Here's a bonus shot of a box of original "new old stock"

Klusons, all with rotting buttons:

Better get back to work . . .

Back to Index Page