|

That was then. . .

Bluegrass Banjo in the '60s

© Frank Ford, 11/7/01; Photos by FF, 2001

Here's something a bit different for the FRETS.COM Museum. It's a regular

1960 Gibson RB-250 right out of the time machine from about 1965, when

it was last played.

What interests me are the fittings -- some original and

some added -- "improvements," at least in 1965. I remember 1965

as if it were yesterday. In fact, sometimes I remember 1965 better

than yesterday, if you catch my drift.

So, let's take a quick trip down that lane and look this

thing over.

|

|

Before the days of the neat and trim "d-tuners" invented and made

by Bill Keith, banjos were often fitted with "cam style" Scruggs pegs.

These were made by Ode in Boulder, Colorado, and were state of the art:

A bit obtrusive visually, these pegs worked extremely well to oscillate between

G and D tuning:

The other four pegs were just about the clunkiest things ever used as banjo

tuners.

They were the top-of-the-line "Sealfast" tuners made by Kluson. These

are the banjo counterpart of the heavy duty tuners used on the Super 400 jazz

guitar. Banjos tend to be a bit "neck heavy" and with these six pegs,

this one is a record breaker.

Another top quality fitting -- the Grover Fifth Peg:

Actually threaded into the side of the neck, and secured with a small wood thread

setscrew driven into a little notch in the side, the Grover was the best fifth

string peg available. Herman Kroll had not yet gotten his geared fifth pegs

in general circulation, so tuning frustration abounded in the bluegrass banjo

community.

If you wanted to get the fifth string up to "C" you were really taking

chances without at least having tack driven into the fingerboard up the neck

a bit. This banjo had one of the new sliding fifth string capos:

Unlike Shubb's later improvement, this capo stuck out from the edge of the fingerboard

and was a bit tentative in holding down the string, depending on the spring

tension and fret height. All in all it worked, and wasn't considered too obtrusive

because most players were not fretting the fifth string with their thumbs in

those days.

Tension and mass. Everything was tension and mass in the 60s. More mass to the

shell and tone ring to project greater highs and overall volume. High tension

on the tailpiece to jam the strings right down against the head for more volume

a the high end. Apparently, this Framus tailpiece (the biggest and meanest one

on the market) was a bit confusing for its owner, who didn't quite get the hang

of stringing it for maximum effect:

Strung this way, the tailpiece itself is jammed into the head, making an effective

mute.

OK, that's more like it:

Nobody outdid Framus when it came to tension and mass. At least it's easy to

switch back to a standard tailpiece, thank Earl.

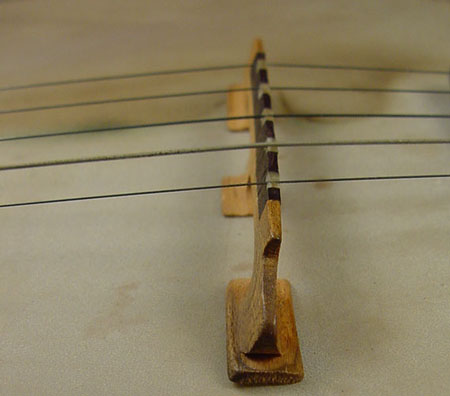

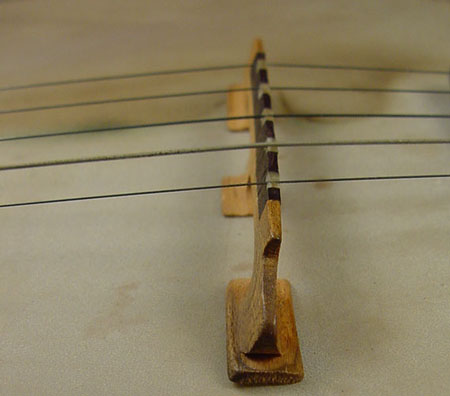

Compensated bridges were a long way off, as were bridges made with "secret"

wood and/or reconstituted powdered rhino horn, or whatever. The simple magic

here is reduction of mass for best efficiency and little fake bone inserts for

brightness:

Load up this skinny little bridge with all the downward pressure of that big

Framus, and it's bound to bend or break!

Back to Museum Main Page

Back to Index Page