I have half a dozen products that I I've designed and sell at wholesale in small enough numbers that it's difficult to find any shop willing to make them in such small batches.

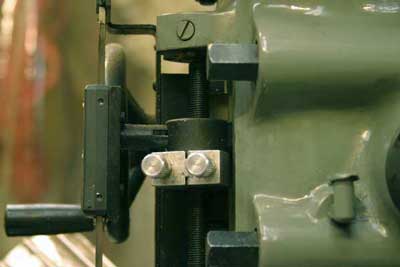

This one is a little jig that guides a regular mill file to cut just the tang

off the end of a piece of guitar fret wire:

|

|

|

I make fifty of these little gizmos at a time, and I'm always looking for a way to save a bit of time on each operation. I have a small tapping head I use for the 1/4-20 and 10-24 screws, but its maximum is 1/4" so I can't use it for the hold-down screw.

Here's the way I cut down on the time to tap the hole for the central screw that holds the fret in position.

The aluminum piece is a 1.25" tall, and the hole is threaded 5/16-18, drilled for clearance half way through.

First I drill the clearance hole, then follow with the tap drill.

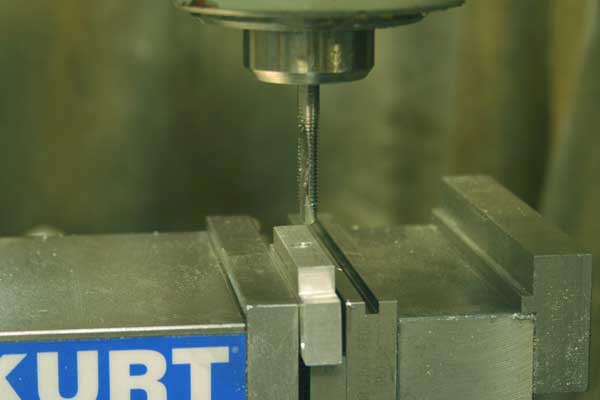

When I have fifty of them ready for tapping the 5/16" hole, I set up my mill by installing the tap in a collet, and bringing it down to the appropriate parallel in the vise, and set the quill depth stop so the tap doesn't quite reach the parallel:

Then I place the part in the vise without tightening it, roughly centered under the tap:

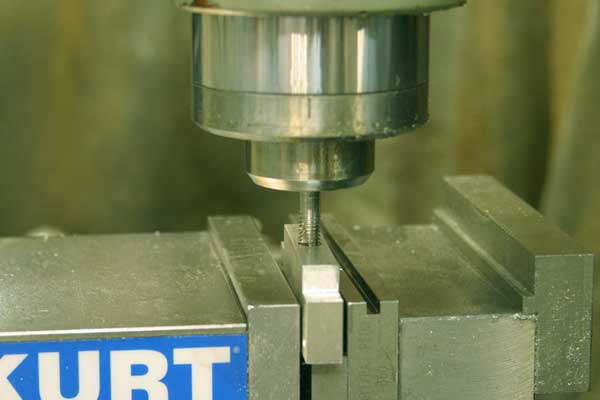

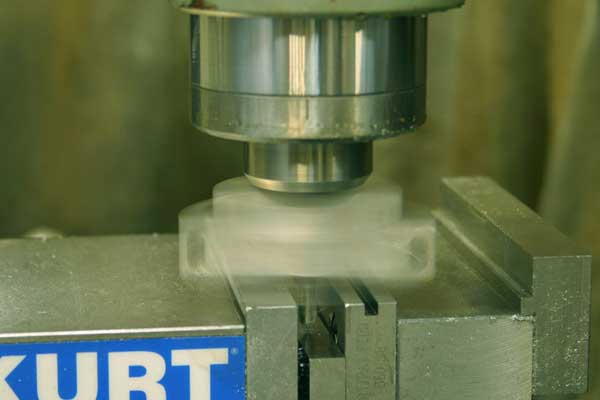

With the spindle running at about 1500 RPM, I bring the quill down smartly, and the tap bites right into the part:

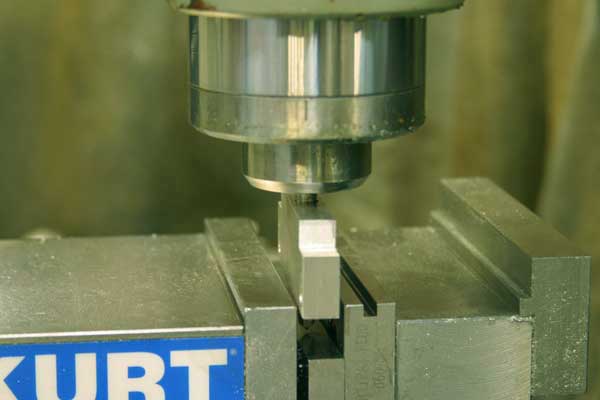

Quick as I hit the quill stop, the tap yanks the part right up:

And out of the vise:

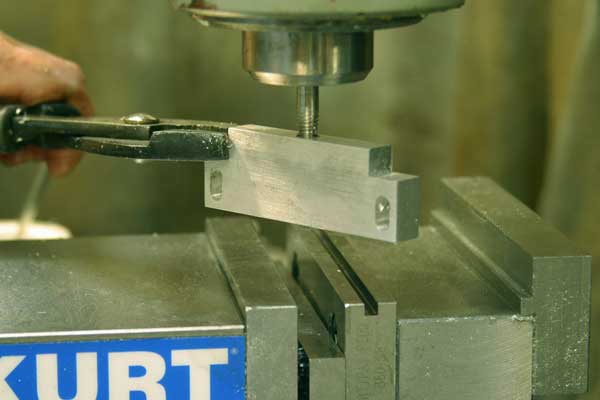

I stop the machine, let up on the quill, grip the part, and run in reverse to eject it from the tap:

Quick, easy, and fun. . .

Disclaimer: Of course, I made sure that the part is symmetrical and would not be out of balance, and that it would spin upward with lots of clearance room. This isn't a technique I use on any other job, but it for this one it does cut the boredom of repetitive work. At low speed, the part doesn't tend to spin up the tap as far to clear the vise, so I keep the RPMs at 1000 - 1500.