Lathe Cross Slide Lock

©

Frank Ford 2006; Photos by FF

How come lathes don't come with locks for the cross slide? My mill has locks for all three axes, and the quill, too, but my lathe has only one axis lock on the carriage (z-axis). This weekend I found myself with another of those projects where I needed to turn a diameter and drill the ends of 200 small brass parts. Last time I did a batch of these things, I told myself I'd never do another until I could lock that cross slide to make the job go more quickly without having to keep an eye on the dials or DRO.

Here's my lathe cross slide - no locking device but at least there were a couple of tapped holes in the cross slide and in the carriage that I figured I could use to my advantage:

So, I rummaged around and found some scrap I could use to make a locking device. First, a nice hunk of aluminum to make an adapter plate for the carriage. I tapped some 3/8-16 holes for my lock to go in various positions, and bolted the plated down to the carriage:

Here's what I came up with for the locking bracket. A hunk of steel left over from when I cut down a Record bar clamp a few years ago, and a piece of a milled aluminum support salvaged (really!) from the old Kay guitar factory around 30 years ago:

I fitted this bit of stuff up to the cross slide thusly:

With a 3/8 socket head screw and a heavy washer, I can really lock the cross slide now:

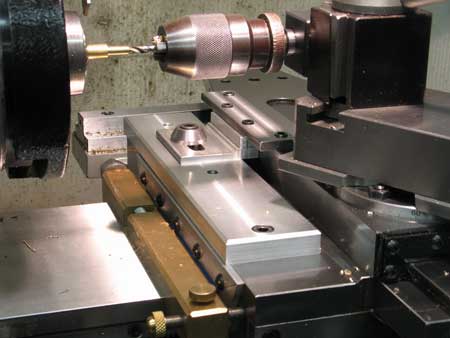

And, here's my little setup in action:

I have the cross slide locked so the drill is dead on center, and I can yank the carriage to the right, open the collet, grab out the part, slip a new one in, tighten the collet, start the lathe and crank the carriage to the left until it hits the adjustable stop. I was comfortably able to drill 200 of these to precise depth in a little over half an hour without readjusting anything or watching any dials. Turning that step diameter went just as easily with my new cross slide lock, too.