Quick and easy does it

Old File Recycled as Form Tool

© Frank Ford 2006; Photos by FF

Not long ago I bought a used Themac tool post grinder from "the usual

Internet source." About the time I first decided to use it, I discovered

that one pulley was missing. , I suppose anybody

who would buy a used tool post grinder would have the lathe and wherewithal

to make a simple pulley. So that's what I did. It was the

smallest one, and since they are used in pairs and I had the other pair and

the mate to the needed pulley, I was able to calculate the size I needed without

too much brain strain.

My new pulley was to be .856" at its maximum diameter, and crowned to

track the flat belt well with its mate. There's enough belt adjustment

that I wouldn't need to be too exact with the diameter, but I did want to get

the crown to match nicely, so I thought I'd concentrate my effort on that part

of the project.

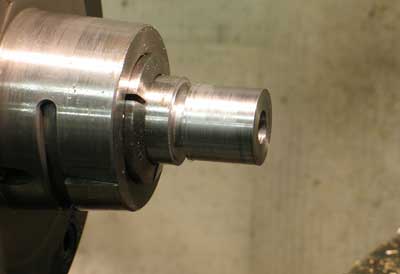

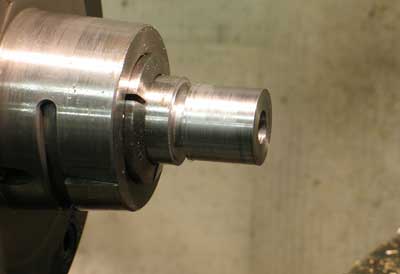

I had a piece of 1" W-1 drill rod in my scrap drawer, so I stuck

it in the lathe collet and got to work. First I faced the end and drilled,

bored and reamed a nice concentric 3/8" hole for the drive shaft. Then

I turned the O.D. to .856" and ran my 1/8" parting tool in about

an eighth inch to establish the width of the pulley:

I must admit I didn't actually measure the width - I just held one of the other

pulleys up next to it as I moved the lathe carriage to the left. When

the ends felt flush, I figured I was good to go. After all, this isn't

rocket surgery. And, to be absolutely sure of concentricity and balance,

I did all the work without loosening the collet.

Now for the fun part. I thought of about a half dozen ways to turn that

convex crown on my little pulley, and finally came up with what I think was

the easiest and quickest way. I rummaged around the shop and found a

seriously dead Nicholson "Handy File." So, I called on it to

volunteer for this assignment. Not high speed steel, for sure, but this would

be a one-use tool, and I could afford the time to hone the edge a couple of

times if I needed to as I went along.

I introduced the file to Mr. Bench Grinder, and roughly ground a concave radius

(the radius of the grinding wheel, of course) in its end. I approached

the wheel at an angle to create a bit of clearance for my new form tool:

The end of the file now had a smooth radius and a good clearance angle, but

the radius was too great to match my pulley, so I'd have a bit more work to

do on it:

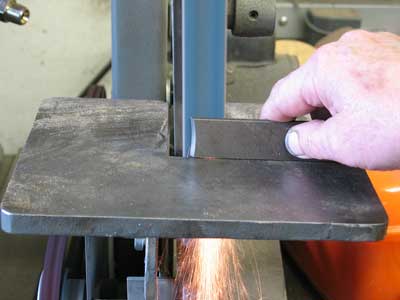

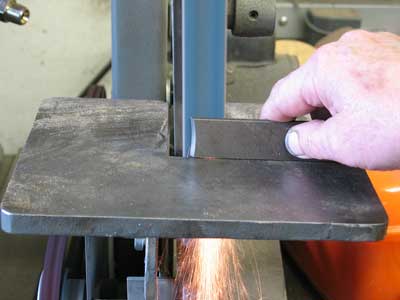

Before correcting the radius, I ground off the file teeth on the top side,

so I'd have a smooth cutter. My 1" x 42" belt sander was just

the ticket:

After interviewing all my various sanding and grinding machines, I discovered

that they were either too small or too big a radius to match the crown in the

pulley, so I chose the upper wheel of the belt sander to adjust the radius

on my form tool:

It was a smaller radius, but by carefully and gently touching the

belt, I was able to reduce the radius on the tool until I could hold it up

to a pulley and see a nice match:

The entire grinding process took around five minutes - less time than it took

to shoot the pictures.

A couple of strokes with a medium grit diamond pocket hone, and I had a right

sharp form tool:

Here's the file-tool, clamped in a double tool holder with the least overhang

I could manage:

This file wasn't

very thick, so any extra overhang would have produced a nasty chatter. I

noticed that while my freehand grinding did a nice job of reproducing the radius

of the pulley crown, I hadn't managed to align the radius exactly on the centerline

of the file. No

problema - I loosened all the setscrews on my tool holder, and ran the tool

right up to the work. Then

I angled the file until both outer corners of my "blank" touched

the curved end. Clamping down all the setscrews, I was certain that the

curved portion would approach the new pulley quite squarely.

To get the file into the holder I had to remove the central stabilizing screw,

which allowed a bit of flex in the holder but not enough to be a problem. I

think now that I like this file tool technique, I'll make myself an extra beefy

holder just for files.

A view from the Sky Cam as I ran the tool in to form the radius on my little

pulley:

Parting off, after a bit of polishing with 600 grit waterproof paper lubricated

with kerosene:

Done - nice and neat, quick and easy: