A large CNC machine cuts the tops to an oversize contour

Those tabs at the waist have index holes so the tops

can fit precisely into various fixtures during the assembly process

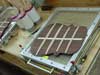

Top braces are glued in vacuum presses.

Bins of CNC machined top braces at the ready.

A full set of top braces, laid up on the press, ready

for the lid to come down with its rubber diaphragm under which the vacuum

will applied.

The same big CNC machine cuts the outline of both the

tops and backs

Here, wood is being graded and matched for backs and

sides.

Laying out the back pieces.

Tops and backs are joined on this "windmill"

clamping rig.

By the time the last back is glued and clamped, the

first one is ready to remove, so this fixture is capable of continuous

output.

The CNC in action.

This back has had the center strip reinforcement applied

and notched to receive the back braces.

Back braces are clamped using similar vacuum fixtures.

A back, right out of the press.

It takes quite a bit of moist heat to make the side

pliable enough to bend, and this press is just the thing to do that job.

It's not a matter of heavy pressure, but a slow controlled

bending process, that gets the job done right.

Many of the tighter bends, cutaways, and special models

are still done by hand on classic old time heated "bending irons."

Another venerable bender.

Here, a cutaway side is bent on a modified version of

a machine designed by Charles Fox.

Bent sides, sitting in precision aluminum molds which

are indexed for precise positioning of neck and end blocks.

Once the blocks are glued and clamped, and the assembly

can be removed from the mold.

Just drying.

Back at the CNC machining center, "kerfed"

linings are cut automatically with a small gang of saw blades.

Linings are glued in place the same way they have been

for generations, using those classic wooden spring clothes pins.

Lots of clothes pins!

After linings are glued in, the sides go back into an

aluminum mold, so they can be held rigidly while the contour of the top

and back radius is sanded.

This horizontal disc sander has the same concave radius

as the top or back.

The aluminum mold fits right into the cabinet, which

is connected to the vacuum dust collection system.

Once in the machine, the mold simply settles down onto

indexing stops to limit the sanding, perfectly defining the contour and

depth of the sides, neck and end blocks where they will contact the top

and back.

Presses for clamping tops and backs.

Each top and bottom plate has a rubber gasket in the

outline shape of the top or back to apply pressure evenly across the joint.

It's fun squishing these bodies up!

A completed body, with its love handles still attached.

After trimming the back and sides, it's time to cut

the channels for the purfling and binding around the body, on a horizontal

shaper.

It takes a lot of different cutter assemblies to accommodate

a wide variety of styles, from the simple "16" to the elaborate

"45."