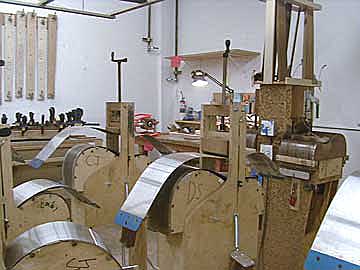

A veritable forest of Fox guitar side benders:

OK, not everything is done by hand. This is the business end of a sophisticated computer controlled milling and carving machine:

This machine can turn out an endless stream of identical parts such as bridges.

Now for the good stuff:

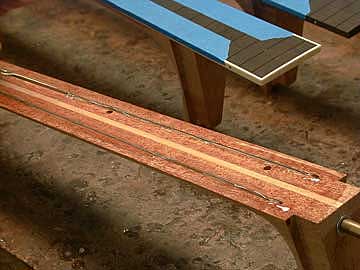

He's installing the truss rods, and some special neck reinforcement that's unique to Collings guitars:

See the two channels outboard from the truss rod?

They are filled with special spring steel reinforcing strips, here being glued in place with epoxy:

Take a look below at the arrow:

These are two pieces of spring steel (they're curved because they come on a roll.) The pieces are .043" thick by 3/8" wide, and are installed two on each side of the truss rod, for a total of 4 bars in each neck. (Small body guitars get .036" thick by 3/8" bars.)

The idea is to provide extra stiffening in the neck. It works.

Here's the latest Collings project:

Mandolins.

And here's Steven Gilchrist (right) consulting on the design of a mandolin building fixture.

Steven and Bill, trying out the finished instruments, and swapping lies: