Page 1 of 6

Not everything, but a helluva lot about

Adjustable Truss Rods

© Frank Ford, 2/10/99; Photos by FF

Topics:

Nonadjustable Rods

Compression Rods

Bending Rods

Adjusting Truss Rods

Maintaining Adjustable

Rods

Truss Rod Nuts, Fittings and

Locations

Nonadjustable Neck Reinforcement Rods

Virtually all steel strung fretted instruments have some sort of neck reinforcement

to keep the neck straight under the load of string tension. A hundred years ago,

that usually meant hardwood laminations. Martin guitars had square ebony reinforcement

inlaid under the fingerboard. Gibson used a triangular cross section insert of maple

in the same postion.

When Martin lengthened their necks to 14 frets clear of the body, they started using

a steel reinforcing rod. First a T-section rod, later a square tube help keep the

neck stable under a variety of conditions:

In 1985 Martin started using adjustable truss rods.

Click

here for more information about Martin neck reinforcement.

This is the modern equivalent of the steel reinforcing rod:

It's a graphite fiber epoxy composite, which is unbelievably strong and stiff, and

very light. Some modern makers use this kind of neck reinforcement, which works quite

well, but does not afford adjustment of neck relief.

Nonadjustable neck reinforcement is really quite simple. It simply makes the neck

stiff so that it doesn't change with age or under the load of the string tension.

Adjustable truss rods are much more complex in their action, but they allow a range

of control over neck relief, and make it possible to make thin necks very stable

and strong.

Compression Rods

The adjustable truss rod was patented by a Gibson employee, and was a standard feature

on Gibson instruments starting in 1922. Adjustable rods of this same design are still

in use today because they are very effective, light and simple.

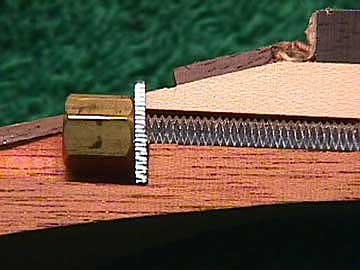

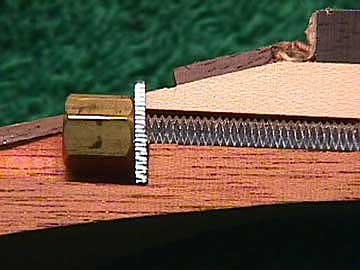

Let's take a look at the "standard" adjustable truss rod, as used in Taylor

guitars:

Here's a longitudinal section of a Taylor guitar neck, showing the truss rod, installed

in a groove under the fingerboard:

That white stuff over the rod is a maple "filler strip" that lays in the

groove on top of the rod to fill the cavity.

This is the adjusting nut at the peghead end:

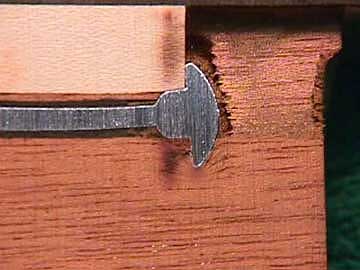

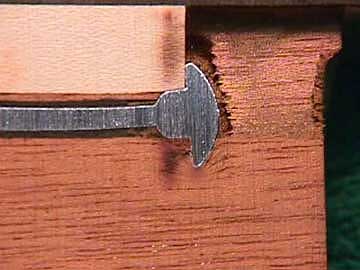

At the other end, the rod is anchored solidly in the neck heel:

In order to describe the action of the rod, I'll use a cross sectional view of the

same system:

Notice how deeply the rod is buried in the neck.

The basic action of the standard adjustable truss rod is by compression of the back

of the neck. When the nut is tightened, the back of the neck is compressed and causes

the neck to bend backward. It is really quite predictable because the back of the

neck has a much smaller cross-sectional area, so it compresses much more easily than

the front. If the truss rod were mounted closer to the fingerboard it would have

to pull harder to compress the back of the neck, but it could still do the job, because

the fingerboard is very dense material and really resists compression.

I hope that makes sense. All adjustable rods work on the same principle. Compress

one side, and something is bound to bend.

More

1

2

3

4

5

6

Back to Index Page