Page 2 of 4

Now to the end of the guitar.

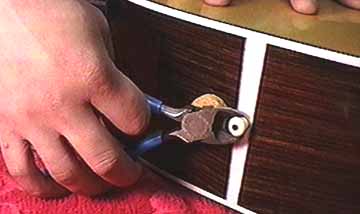

First, he removes the end pin, which is tightly fitted in a tapered hole. He can

pry it out with a pair of diagonal cutters bearing on a cork pad to protect the finish:

The hole in the end block must be enlarged to 1/2" diameter, and drilling would

be very risky. We've seen any number of instruments with big chips ripped out from

well intentioned but unskillful drilling!

Mike's going to use the specially designed reamer from Stewart-MacDonald because

there's absolutely no possibility of tearout from this fine tool:

It's a reamer that tapers for most of its length, but ends in a straight section

exactly 1/2" in diameter. That way, the hole is gently enlarged to a very clean

cylindrical hole.

In fact, the pickup fits more precisely in a 15/32" hole, and Stewart MacDonald

has just introduced a reamer with 15/32" final diameter. But, the 1/2"

size works just about as well, and with the slight extra room in the hole the strap

jack assembly is "self-aligning" as the nuts are tightened. That's handy

in case the hole is not exactly perpendicular to the neck block.

Here he goes:

Once the hole is drilled, Mike sticks a pencil in from outside to "fish"

out the pickup he's holding inside the guitar. It's easy to find the hole this way,

because he's working "blind" with his arm filling up the soundhole:

He sticks the jack through from the inside, pulls it back out, and sets the internal

nut to the right spot to get the jack to stick through the exact amount necessary:

This may take a couple of trial fittings, but it's quick work, and vital to the mounting

of the strap jack.

More

1

2

3

4

Back to Index Page