Fingerboard Top Crack

© Frank Ford, 2/14/99; Photos by FF, 2/13/99

The patient is a 1940s Gibson guitar, with an all-too-common crack in the top, right alongside the fingerboard:

This crack had been glued up, and the guitar refinished some fifteen years ago. Now the crack is starting to show through the finish because it has come loose again. From the end of the fingerboard to the soundhole the crack is open, but the rest of it appears to be tightly glued. I suspect this guitar has been exposed to some excess heat because the finish is deformed over the crack, but not actually broken. Fortunately, the two sides of the crack have not moved longitudinally.

I'm very concerned about this particular crack, because the end of the fingerboard has quite a load on it from the string tension. If the braces under the top were to loosen in this area (say, in the high heat of a parked car) the string tension would cause the fingerboard to push the middle of the top forward, taking the neck block with it, and radically changing the neck angle. The soundhole rings would buckle, break, or pop out. Then, we'd have a real mess.

As it is, there's no immediate danger, and now's a good time to reinforce the area.

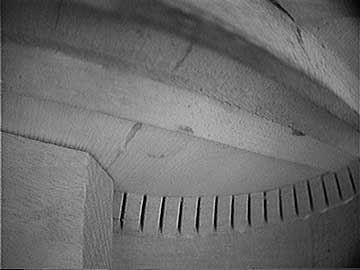

Here's a view from the inside:

Notice that the top center joint has separated as well.

Further back, you can see the rest of the crack where the glue is still holding well.

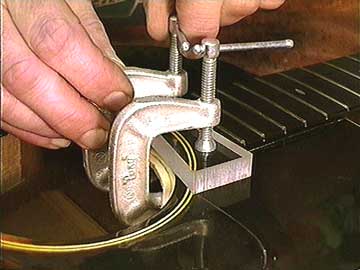

I'll clamp a piece of spruce under the edge with the grain oriented perpendicular to the top grain:

I'm using a long enough reinforcement piece to bridge over the loose center joint as well.

I want to be sure my new patch holds tight and will avoid creeping under the load, so I'm using hide glue. Hide glue can't creep even at elevated temperatures, as regular aliphatic resin wood glue can.

I was careful to trim the patch to fit neatly against the interior braces, but I left it overhanging into the soundhole. I find it easy and neat to trim the patch once it's in place, and the wider patch is easier to clamp well.

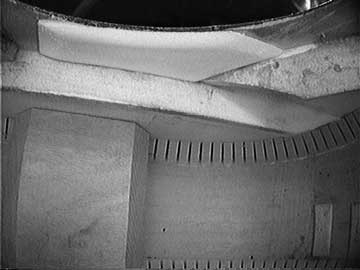

I can adjust the amount of bevel on the edge of the patch, so that it's not obtrusive when you look through the soundhole in that area:

Inside, it looks pretty neat, too:

Next, I'll add a couple of reinforcements to the rest of that long crack. I'm not concerned with affecting tone by adding braces in this dead area of the top, and I want to make certain that the top is stable under the load of string tension.

On the next page, I have some pictures of a similar crack repair on a Takamine, showing what happens when the crack is left unattended. . .

More