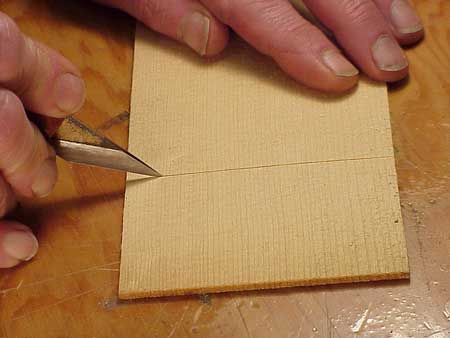

Here I have a piece of 1/8" thick spruce. I draw my knife firmly over the face of the board, and flip it over and repeat the process:

I'm not measuring, and I'm not using any guide. I keep the cuts aligned (sort of) by holding the knife down on the board, continuing the cut around the edge as I flip it over.

It breaks easily at the cut:

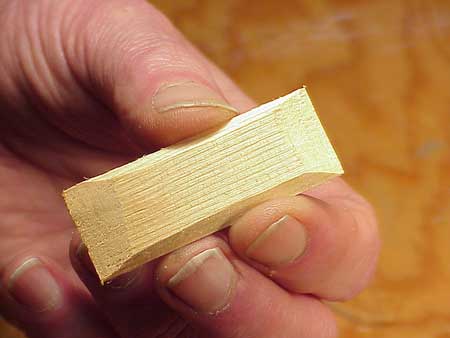

See, the cuts aren't really aligned at all, but it doesn't matter for this use:

It's easy to split off a chunk:

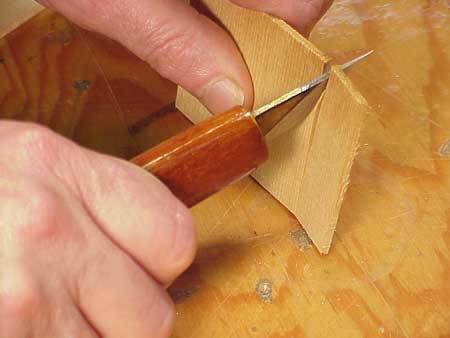

Here's another cut that takes too much force for the hobby knife to handle:

It's a hard push but a very easily controlled one. In one quick motion, I have a bevel on the end.

A more delicate bevel on the edge:

And I have a nice little rectangular reinforcement "cleat" that will clean up nicely with just a few strokes of sandpaper

While builders are turning more and more to "precision woodworking" with jigs, fixtures, power tools and even CNC machining, it's clear to me that in general the repairer is bound to be more efficient, flexible and successful with hand techniques.