Bridge Regluing

© Frank Ford, 4/4/99; Photos by FF, 3/27/99

If you're not familiar with traditional hide glue, read the Hide Glue Page.

I don't happen to have a good "before" picture, so just suffice it to say that this 1964 Martin 0-16NY had a loose bridge.

Here are some interesting photos of loose bridges.

In order to remove the bridge with as little damage as possible, I like to heat it:

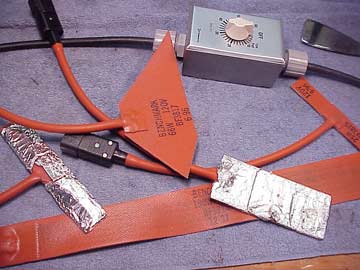

I have this special 1" x 6" rubber heat blanket, which I've wrapped with aluminum foil to keep it clean because heating rosewood bridges tends to release a lot of resin that bakes right on the rubber. On the ends I have a couple of little lead weights to hold the heater down.

Usually, I protect the top with a bit of masking tape and light cardboard, in case the lead weights were to slide off. I've left that stuff off for the photographs.

L.M.I. is a great source for these little rubber heat blankets, by the way. They sell a kit that looks like this:

There's a timer so you don't get distracted and leave the thing on long enough to burn the house down. Don't laugh, burned instruments are really common if you forget and walk away.

As the bridge is heating, I check it with my special putty knife:

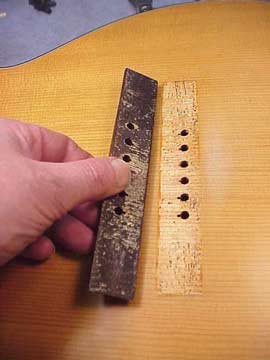

Soon as I feel the glue giving way, off comes the heater and off comes the bridge:

See? Nice and neat:

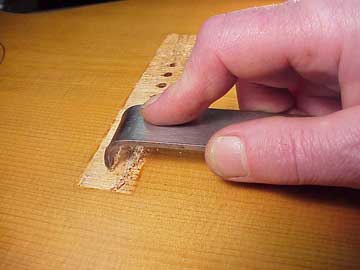

I have a little scraper I made from a piece of high carbon steel. It's just a bent hook, sharpened to about 45 degrees. I touch up the sharp edge with a diamond pocket hone, and carefully scrape the gluing surface:

I go for as much gluing surface as possible, so I scrape carefully right to the edge where the bridge sits. Some manufacturers have the a portion of the bridge sitting right on the finish. It looks neater that way, but I'm putting function ahead of form, especially because the bridge glue joint had already failed. Even if the surface appeared perfectly clean I'd scrape lightly to remove any oxidation that might interfere with glue adhesion.

More