Page 2of 5

Back to the job itself. I'm using my flexible knife to pry carefully at the back,

and loosen it all around:

The binding comes just to the joint between the back and sides, so I don't have to

remove the binding. A ninety year old mandolin usually comes apart with the back

intact, and this one was no exception.

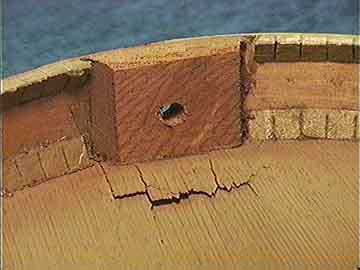

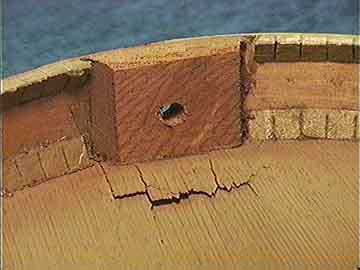

Inside, it's really easy to see the terrible damage done by the fall and subsequent

string tension:

My first order of business was to glue all these cracks back together. It wasn't

easy, but working one by one I managed to get them aligned and glued up. Most of

them required no clamping to keep them aligned while the glue set.

By the way, I'm using traditional hide glue for this entire repair because I think

it's the superior adhesive for the job, being very rigid and not sensitive to heat.

After all, the mandolin was originally build entirely with hide glue, and that's

what a future repairer will expect to find in here.

All the cracks are glued up except this nasty one. It's out in

the middle of the face, and there's no way to clamp it shut while the glue sets:

Or is there?

I've released the top from the end block now, so I can do a bit of tricky clamping.

First, I'll swab a little cyanoacrylate catalyst (accelerator) on the area around

the crack, being extremely careful not to let any actually run into the crack:

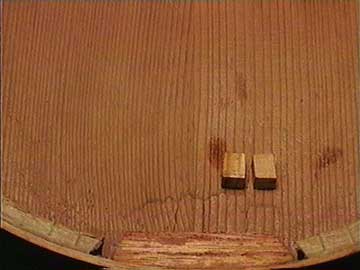

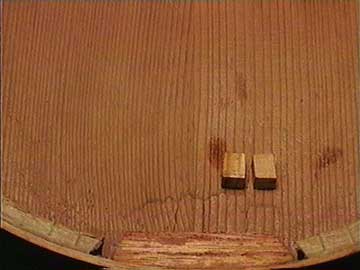

Next, I put a drop of medium viscosity cyanoacrylate on the bottom of each of two

little scraps of wood, and stick them right to the top, where they bond instantly:

Now, I have two little flat surfaces to mount my tiny c-clamp:

I coat the crack with fresh hot hide glue, and clamp up!

Next day, after the glue dries, I chip off the little scraps and scrape off the residual

cyanoacrylate glue.

More

1

2

3

4

5

Back to Index Page