Now, I've scooped out a lot of the top:

In the damaged area, I've cut the top very thin indeed.

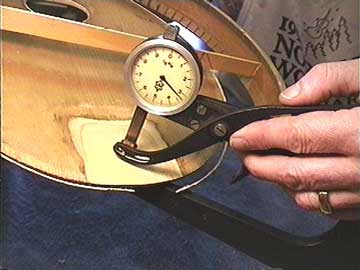

It's hard to see the place where I cut the top away, but it's a dished area around the damage. As you can see by my thickness gauge, I've left only half a millimeter of thickness in the cracked area:

Talk about fragile! I can't wait to get something glued to this.

I got ahold of some fine grain spruce,and split it:

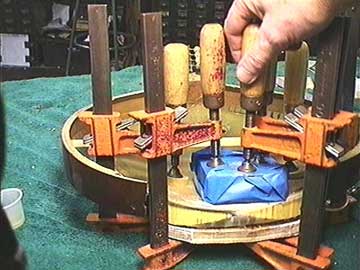

The idea is to get some thin pieces with absolutely no grain runout for extra strength. I then sanded the pieces down to 0.5mm thick, and clamped them, one by one, gluing and laminating them into the dished area I cut out:

With a soft resilient pad on top and my hard plaster cast underneath, I'm assured that the laminations will conform and the top will be restored to its original contour.

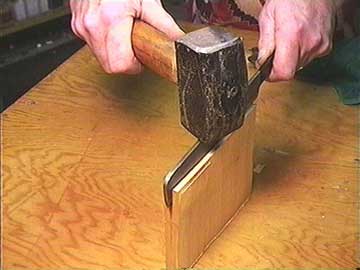

Working with my little finger plane, I'll level and graduate the area to its original thickness:

Now I have reinforced the area with laminations of spruce for strength and I haven't added any extra thickness to the top in that area, so there will be minimal effect on the tone.