Here are my bridge plate removing chisels:

The big one is a 10-inch file I heated with a torch and bent, then ground the end to a chisel. The small one is a piece of 3/32" high carbon steel I shaped the same way, and hardened by heating and quenching it in water.

For more detail look at the bridge plate replacement article.

Working with these tools, I pry and lift the heated bridge plate loose from the top. Often, the bridge plate splinters and comes out in sections. This bridge plate is laminated, and came out quite neatly:

But, just look at where the bridge pin holes are. They're right at the back edge, just the way they are on the bridge itself. That means the top has a tendency to "hinge" right behind the bridge where all that string tension is concentrated.

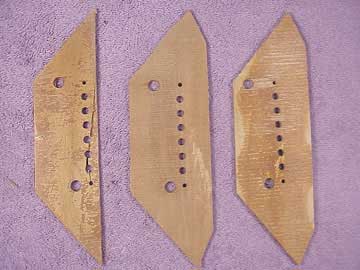

Compare the bridge plate I just took out with a couple of other Gibson bridge plates from similar Gibson guitars with the same adjustable bridge setup:

The one on the left came from this Hummingbird. The other two, while differing in the location of the holes, both extend substantially behind the bridge, giving support to the top where it's actually needed.

Look at these views of some Gibson bridge plates

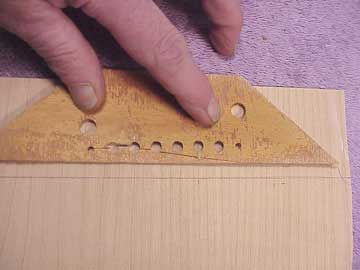

I'm going to give this guitar a bit of help in that area, too. I trace the old bridge plate on a piece of 1/8" thick maple, moving the alignment "forward" just a bit, to allow the back of the new plate to extend further behind the bridge:

Notice the grain direction of the maple. My new plate will have the grain parallel to the top of the guitar, so that it will be better able to resist the relentless pull of the strings. Wood has essentially no rigidity across the grain, so I feel that bridge plates should have the grain parallel to the string tension, hence parallel to the grain of the top.

You can see the amount of extra support area I'm allowing behind the bridge:

And, because I don't want to increase the size of the bridge plate, the front edge falls short by the same amount:

Unlike Gibson, I'll bevel the edges to make it look a bit neater, and to help it resist "peeling" loose if it's subjected to the stress of high heat (as in a parked car).

More